Multifunction Top Drive CBM Drilling Rig With 5Rod 1800m 1500m

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Multifunction Top Drive CBM Drilling Rig With 5″Rod 1800m – 1500m

<stron

Multifunction Top Drive CBM Drilling Rig With 5″Rod 1800m – 1500m

Description:

TDR -80 is mainly used for coal bed methane exploration, water well drilling, rescue well drilling, shallow oil and gas, mine exploration drilling etc.

The TDR-80 multifunction top drive rig enables each user to drill with following methods, with borehole diameters of 4″(108 mm) to 47″(1 200mm) and drilling depths up1500m

Rotary-drilling with direct circulation

Rotary-drill with reverse circulation

Auger drilling

Percussion core drilling(ram coring)

Wire line core drilling

Down-The-Hole hammer DC and RC drilling

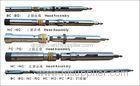

Drilling Depth Guidelines

Use 5″rod 127mm 1800 – 1 500 m

Use 4-1/2 ″rod 2000– 2400 m

Use 4″rod 2800 – 3200 m

The figures in these tables have been calculated, based on field experiences, based on a vertical, straight, and clean down hole. Actual drilling capacity will depend on in-hole tools, conditions, drilling techniques and equipment used.

| Mounting | |

| Crawler, Undercarriage of Excavator. | |

| Moving Speed | 3 Km/h |

| Power Unit | |

| Diesel Engine | STEYR-WEICHAI Diesel engine, 2 valves, turbocharged intercooled. |

| Power | 276kw *2 set |

| Cylinder and Displacement | 6 cylinders, 9.726 L |

| Capacity of Fuel Tank | 680 L |

| Mast | |

| Length of Mast ( Fully Expanded) | (20m) |

| Length of Mast (Fully Retracted) | (14m) |

| Stroke of Feeding | (14 m) |

| Stoke of Mast Slipping | 143.7″(3.65m) |

| Rod and Casing | (5.49-6.7m),(8.23-9.144m),( 11.58-13.71m ) |

| Feeding System | |

| Capacity of Pull Back Force | 800 KN |

| Capacity of Pull Down Force | 180 KN |

| Max. Pull Back Speed | 80 m/min |

| Max. Pull Down Speed | 35 m/min |

| Drill Head | |

| 4 Shifts, 8 Speeds | |

| 1st shift | 270 - 600 RPM 7700-4300 Nm |

| 2nd shift | 150 - 280 RPM 7700-13700 Nm |

| 3rd shift | 95 – 170 RPM 12500-22000 Nm |

| 4th shift | 60 – 110 RPM 18000-33600 Nm |

| Luffing Angle of Drill Head | 0 - 90º (from perpendicular to level) |

| Main Winch | |

| Line Pull | 30 KN |

| Wire Rope Diameter | 14 mm |

| Wire Rope Length | 45 m |

| Coring Winch | |

| Line Pull | 15 KN |

| Pull Speed | 0-280 m/min |

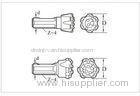

| Power Tong | |

| The tongs are designed and manufactured according to API SPEC 7K standard Specification for Drilling and Well Servicing Equipment”. | |

| Size Rang | 127-203 mm |

| Max.Torque | 100 KNm |

| Rotation Speed | 2.7 – 40 RPM/min |

| Dimensions and Weight | |

| Length in Transport / Working Position | 13.8 m / 9.8m |

| Width in Transport / Working Position | 3.2m / 3.2 m |

| Height in Transport / Working Position | 3.4m/19.8 m |

| Weight | 58 000 Kg |

Main Components Description

General

The TDR-80 is mounted on the undercarriage of excavator with a total weight of 58 ton. The engine power 552 Kw.

Mast

Constructed of high tensile steel and hydraulically elevated, lowered and setting by four (4) double acting hydraulic cylinders. The mast is equipped with 4 guide rails for the carrier of the drill head and a suspension for the feed device. The rig also is equipped slipper system, in order to the mast slip, and the stroke is 3.65m, lead to the mast can support on the ground. The rig can set up the blowout preventer and other system.

Mud Line System

All mud lines on the TDR-80 Drilling Rig have 3" (76.2mm) diameter, in order to reduce friction losses to a minimum.

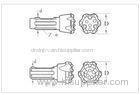

Top Drive head

Top drive head suits for tricone bit, DTH hammer, PDC Dill bit and diamond bit which meets special demand of rotate speed and torque during work. The 4-shift Gearbox using spur gear drive, oil bath lubrication. Hydraulic Motor and gearbox could provide for much high speed and torque to be adjusted.

The angle of rotate unit could be adjusted as needed, ranges from 0º(vertical)--90º.

Electrical System

Generator and batter driven by diesel engine altogether provide 24V direct current. All cables are protected by seal line. Furthermore, all circuits are equipped with short-circuited.

Additional Rig Components

TDR-80 Rig can be modified. All kinds of aggregates, required for different drilling methods, can be installed on the rig at customer request, or supplied as stand-by aggregates.

Related Search

Find more related products in following catalogs on Hisupplier.com

Company Info

Sinocoredrill Group Co.,Ltd [China (Mainland)]

Business Type:Manufacturer

City: Wuxi

Province/State: Jiangsu

Country/Region: China (Mainland)