Wireline Heat Treatment HWT / Q Series Geological Core Drilling Rod And Casing Tubes

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

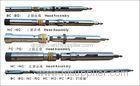

Wireline Heat Treatment HWT / Q Series Geological Core Drilling Rod And Cas

Wireline Heat Treatment HWT / Q Series Geological Core Drilling Rod And Casing Tubes

Description:

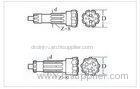

Our wireline drill rods are all manufactured by CNC machines under DCDMA standard. They're made of

high quality alloy steel with heat-treated. We also can produce various sizes of casing tubes.

Drill pipes will be manufactured from seamless steel tube by cold drawn.

The material is XJY850 / 30CrMnSiA which is one of the best material for geological drilling in China.

Coring rods are crafted from quality heat treated materials ensuring superior wear resistance, strength,

and toughness in the most demanding applications.

Rods and casing are manufactured under stringent industry standards, and are field tested under a variety

of conditions.

All rods are designed to be compatible with other rods manufactured to DCDMA standards.

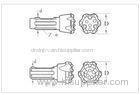

Specifications:

1. high quality alloy tube

2. thru-wall heat treated tube body

3. consistent concentricity, straightness

4. tapered threads

Raw materials:

SINOCOREDRILL only choose the best steel tubes in the market to manufacture our rods and pipes. Spot check will be conducted after the steel tubes delivered to company. We will make sure the compositions and specifications match the inspection report form the suppliers.

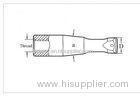

Heat treatment control:

Heat treatment will greatly improve the material strength and increase the thread wear life of the rods and casings. We conduct either tru-wall or both ends heat treatment to the tube body. After heat treatment, strength, hardness, straightness and concentricity of the treated tubes will be tested in our lab.

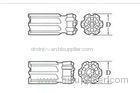

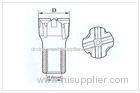

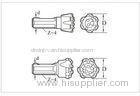

Thread opening process:

Accuracy of threads will determine the use effects and life time of drill rod and casings.

CNC latches and form cutter are used in thread opening processing to minimize error made by anthropic factors.

Additional thread treatment:

Surface of the threads will be cleaned to remove burr adhered after threads are opened.

Afterwards, the tread surface will be phosphated to improve surface conditions.

Specification :

| Steel grade :30CrMnSiA NQ Drilling Rod | ||

| Rod Size:(mm) | 70.1*5*3050 | |

| Rod OD/ID (mm ) | 69.9/60.3 | |

| Rod length (m) | 1.5 or 3 | |

| Rod thickness | 5.5 | |

| Rod Weight (kg/m) | 8.8 | |

| Thread length (mm) | 42 | |

| Thread pitch (thread/inch) | 3 | |

| Box thread tooth height | 0.76 | |

| Pin thread tooth height | 0.88 | |

| Thread tooth angle (°) | 29° | |

| Tensile Strength (Mpa) | 960 | |

| Yield Strength (Mpa) | 840 | |

| Elongation(%) | 18 | |

| Hardness (HRC) | 30/30 | |

| Material | 30 CrMnSiA | |

| Heat treatment | Entire-length or ends thermal processed | |

| Maximum core depth (m) | 1500 | |

Packing

Concerning the packing, it is packaged by iron belts.

BQ Bundled Specifications (Steel Belt):

3.0m/10ft BQ Drill Rod (37 Pieces)

Dimensions (L×W×H): 3.0×0.4×0.4

Volume: 0.5 m3

Gross Weight: 670 kg

BQ Bundled Specifications (Iron Frame):

3.0m/10ft BQ Drill Rod (30 Pieces)

Dimensions (L×W×H): 3.0×0.35×0.3

Volume: 0.32 m3

Gross Weight: 550 kg

NQ Bundled Specifications (Steel Belt):

3.0m/10ft NQ Drill Rod (37 Pieces)

Dimensions (L×W×H): 3.0×0.5×0.5

Volume: 0.75 m3

Gross Weight: 900 kg

NQ Bundled Specifications (Iron Frame):

3.0m/10ft NQ Drill Rod (25 Pieces)

Dimensions (L×W×H): 3.0×0.38×0.39

Volume: 0.43

Related Search

Find more related products in following catalogs on Hisupplier.com

Company Info

Sinocoredrill Group Co.,Ltd [China (Mainland)]

Business Type:Manufacturer

City: Wuxi

Province/State: Jiangsu

Country/Region: China (Mainland)

You May Like:

Sitemap XML

About HiSupplier Help Center Customer Service Friend Links Site Map Archives

Browse by: China Suppliers - Hot Products - Products Directory - Offers Directory - Suppliers Directory - Buyers Directory

Language Option: العربية - Nederlands- Français- Deutsch- Italiano- 日本語- 한국의- Português- Pусский- Español